NC Numerical Control Tube Pipe Prefabrication Cutting and Beveling Machine

Package Size 200.00cm * 150.00cm * 200.00cm Package Gross Weight 600.000kg OCM Stationary NC High Speed Pipe Cutting and;

Basic Info.

| Model NO. | OCM CND |

| Control | Semi-Automatic |

| Application | Metal |

| Power Source | Electric |

| Layout | Stationary |

| Transport Package | Wooden Case |

| Trademark | Co-Pack |

| Origin | Wenzhou, China |

| HS Code | 8461909000 |

| Production Capacity | 500 Sets/Year |

Packaging & Delivery

Package Size 200.00cm * 150.00cm * 200.00cm Package Gross Weight 600.000kgProduct Description

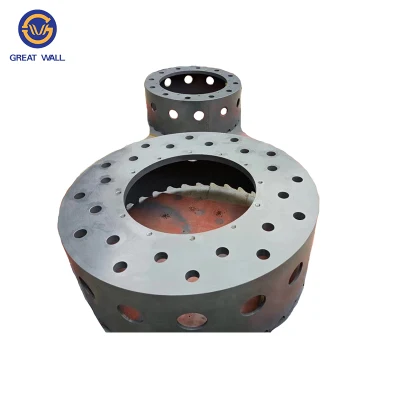

OCM Stationary NC High Speed Pipe Cutting and Beveling MachineOverviewCo-Pack OCM Stationary pipe cutting and beveling machine is a practical and durable pipe cutting beveling machine. It was developed cutting and beveling for pipe prefabrication. Adopt variable frequency motor drive, electric clamping system, self-centering system, electric up-down system. It is suitable for the processing of U, V, J, Y and beveling shape of carbon steel, stainless steel and alloy steel pipes. Pipe length setting system and pipe conveying system are optional. Advantage with high speed, high precision, high quality of cutting, easy to control. It is the key equipment for all kinds of pipe prefabrication. Suitable for cutting and processing pipe of oil, chemical, natural gas, nuclear power and other industry.Features5 models are available in pipe OD: 30-914mmCold cutting, don't influence the pipe's materialSimple button-type controller, easy operationElectric clamping system, self-centering, precision solidAutomatic feed and manual feed can be optioned.Built-in water cooling systems, increasing the life of machine and tools.Varity of beveling shape: "U", "V", "J", double "V", compound bevels.Cutting and beveling, and can be used for cutting, beveling, double beveling.Machine up/down design, perfectly adapted to different diameter in the same pipe conveyerCapabilityPipe cut offPipe end bevelingPipe facingCutting and bevelingCompound bevelingCounter boringGroovingBeveling ShapeOther beveling shape, angle and pipe material, please declare before orderThe key words of this product: Pipe beveling machine Tube beveling machine Pipe prefabrication production lineModel and Specification

| Model | Working Range | Wall Thickness | Rotating | Motor Power | ||||

| OD mm | mm | rpm | Cutting kw | Clamping kw | Up/down kw | Feeding kw | ||

| OCM-168 | OCM-168-II | 30-168 | 3-20 | 0-50 | 2.0 | 0.75 | 0.75 | 0.75 |

| OCM-325 | OCM-325-II | 50-325 | 5-25 | 0-30 | 3.0 | 0.75 | 0.75 | 0.75 |

| OCM-508 | OCM-508-II | 219-508 | 6-30 | 0-20 | 5.5 | 0.75 | 1.5 | 0.75 |

| OCM-610 | OCM-610-II | 273-610 | 6-30 | 0-15 | 7.5 | 0.75 | 1.5 | 0.75 |

| OCM-914 | OCM-914-II | 610-914 | 6-30 | 0-10 | 7.5 | 0.75 | 1.5 | 0.75 |

| Form Type | Insert Type |

| Material: M42 or M35Kinds: Cut off, beveling, Double beveling, Compound bevelingAngle: 0°, 30°, 37.5°, double 30°/37.5°, 37.5°+10°Length: 90mm, 150mm, 200mm | Material: Tool holder: 40Cr; Insert: CSS or CarbideKinds: Cut off, beveling, Double beveling, Compound bevelingAngle: 0°, 30°, 37.5°, double 30°/37.5°, 37.5°+10° |

You may also like

Send inquiry

Send now